Understanding Argon

Sacramento Sparks Reno Welding Supply

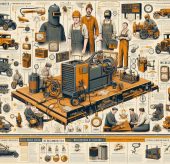

Welders use various industrial gases while on the job. Different gases are needed for different projects and that’s why Harris Gas stocks so many options. We want to be your one stop shop for everything you’ll need as a welder. Some of the industrial gases we move quite frequently are Carbon Dioxide, Helium, and Argon. Today we’re going to dig deep into one of the gases we sell the most of, Argon.

Argon is used primarily when welding stainless steel and aluminum. Argon is also used on carbon steel with arc stability and continuous metal transfer from the weld pool’s electrode. Many welders will tell you that Argon is the top choice for TIG welding and one of the best choices for shielding gas for MIG.

Shielding gas is primarily used when referring to Argon and is something that can be incredibly beneficial for any kind of project. Shielding gases are basically a type of classification given to inert or semi inert gases. When metals are met with high temperatures, they can react against some gases in the air around it. In situations like these, shielding gases like Argon is applied to the metals so they don’t react with the rest of the components in the air.

Argon is relatively safe as it is non-flammable and emits nothing toxic. Argon won’t burn when exposed to any heat, flame, or sparks. This is part of the reason why welders love it so much. It has great benefits and usage is low risk. The one thing to be cautious of is that when using Argon, remember that it’ll increase the density of the air around you. It’s best to use Argon, and any gas in general, outdoors or in an area with ample amounts of ventilation.

Argon is a great resource for welders and any welding project. If you need cylinders please stop by our store and we’ll be happy to help you out!