Underwater welding has played an important part in the welding trade for many years. “Wet” welding, can be characterized as work completed in open water, while “hyperbaric” welding is either carried out in a dry and specially designed pressure enclosure or in open water. Miller Welders has the supplies and specialists for all forms of welding equipment and techniques, including those used for underwater work.

Welding underwater is demanding work, requiring a particular set of skills and techniques, and is usually associated with shipping and assembling or repairing structures like tankers and offshore oil rigs. Underwater welding is necessary, but it is not without an element of risk. For further details related to this risk factor, contact Lincoln Welders, experts in all forms of welding.

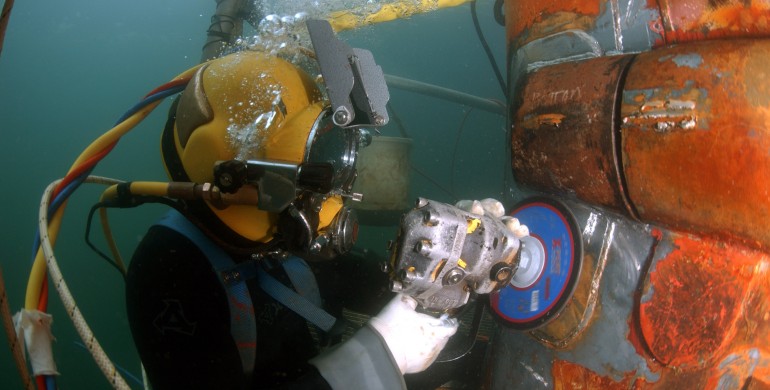

Manual arc welding is usually used when welding underwater. This type of application is an adaption of protected metal arc welding, employing a waterproof electrode. Welding specialists, like Miller Welders, are well versed in flux-cored arc and friction welding, processes used for this type of work. In both methods, the operating power supply for the welding equipment is connected by way of cables and hoses.

Hyperbaric, or dry underwater welding—a process used specifically in high pressure environments—can be conducted in open water, but is usually performed within a specially constructed hyperbaric, dry chamber. It is a technique that, like wet welding, is used in assembly and repair work on pipelines, ships, offshore oil rigs, and barges. Modern hyperbaric chambers are transparent enclosures covering the weld area, with water evacuated by pumping gas into the chamber.